Can photovoltaic inverter isolating switches really effectively prevent fires?

- Sangtian New Energy shines at 2024 SNEC Exhibition

- Sangtian New Energy shines at 2025 SNEC exhibition

- 浙链全球启新程|信基电气携手生态伙伴共拓出海新格局

- Photovoltaic Rapid Shutdown Device (RSD)

- Overview of Photovoltaic DC Combiner Box

- Five key points to help you accurately select molded case circuit breakers to ensure circuit safety

- Introduction to photovoltaic circuit breakers

- Can photovoltaic inverter isolating switches really effectively prevent fires?

Since the beginning of this year, various inverter manufacturers have successively released inverters equipped with DC protection switches. Different experts in the industry have discussed the protection capabilities and standard compliance of DC side switches, with differing opinions. Several media outlets have also reported on this topic.

The main focus of the debate lies in whether it is safe to achieve safety solely through isolating switches, without adding protective devices such as fuses or circuit breakers, under the system design where the number of strings connected to a single MPPT exceeds two?

Nowadays, such products are already being applied in actual power stations on the market. How about their actual protection capabilities? The author conducted reverse connection and reverse injection tests on site to verify the system's safety performance in practice.

1. String Reverse Connection Test Verification 1. String Reverse Connection Test Verification

Inverters often encounter situations such as reverse connection, misconnection, and short circuit during actual construction, installation, operation, and maintenance, which can easily pose safety risks. Therefore, the system protection capability of the equipment is crucial.

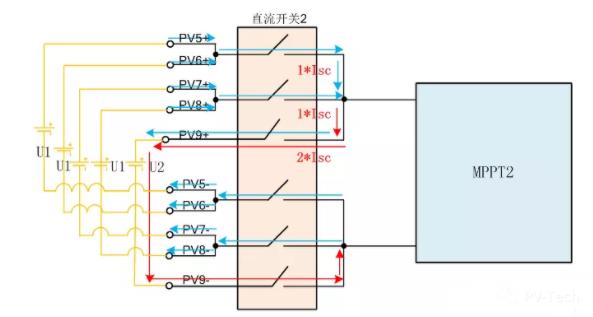

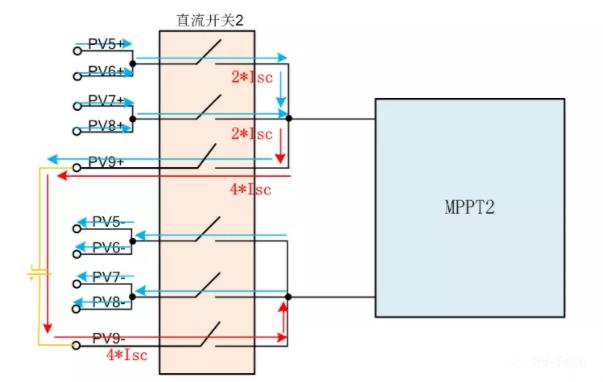

The selected equipment has each MPPT connected to 5 strings of photovoltaic modules, with a single string current of nearly 20A on site. One string of the selected equipment underwent positive and negative reverse connection tests. After reverse connection, this reversed string formed a loop with the other 4 strings, and the currents of the other 4 strings all flowed backward to this string, creating a reverse current of 70A.

Circuit diagram for string inverting test Circuit diagram for string inverting test

After the first test trigger, the isolating switch underwent a protective action, but it tripped after 240ms, indicating a discrepancy with the manufacturer's advertised 15ms switching-off capability.

After the second test trigger, the isolating switch failed to trip, resulting in protection failure and persistent reverse current. This led to a sharp increase in the temperature of the components within the corresponding string. One of the components' diode exceeded 150°C and exploded on the spot. Such faults pose a fire risk.

2. String reverse irrigation test verification 2. String reverse irrigation test verification

Currently, most photovoltaic power stations are located in complex environments. Due to the large area of photovoltaic modules installed in these stations, various factors such as uneven illumination, obstruction, and module aging often occur. The inconsistent light reception or power generation among different modules can easily lead to voltage differences in the strings, which can trigger current backflow. If effective protection is not provided, it will pose a system security risk.

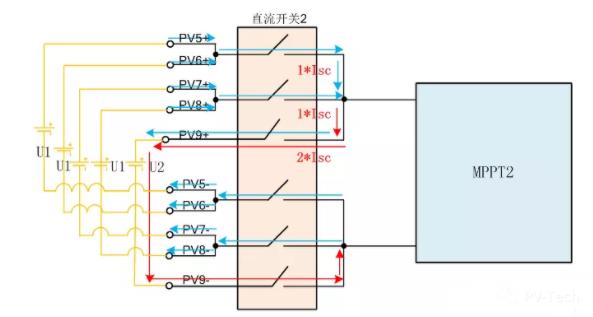

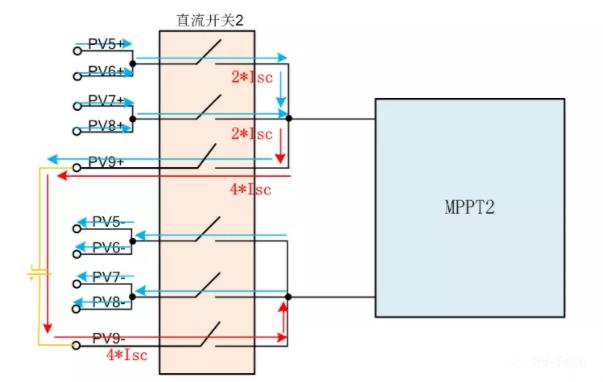

Therefore, one string of the inverter was selected for the backflow test, with one string of components maintaining a certain voltage difference from the other four strings in the same MPPT. This voltage difference caused current to backflow into the faulty string from the other four strings, with the backflow current reaching 30A. Three rounds of tests were conducted under the above conditions.

Circuit diagram for string inverter test

After the first two test triggers, the isolating switch underwent a protective action, but it tripped after 250ms, which is significantly different from the manufacturer's claimed 15ms shut-off capability.

After the third test failure, the isolating switch failed to trip, resulting in protection failure. The temperature of the corresponding components and circuits rose sharply, with one component experiencing a temperature surge of 49°C (rising to 76.8°C) within one minute. If it cannot be disconnected in time, the temperature will continue to rise, potentially causing the component to catch fire and burn.

The aforementioned experiment proves that when one MPPT is connected to more than two strings of components, the isolating switch cannot provide effective protection, which can easily lead to component damage, fire, and even greater risks.

In summary, isolating switches can enhance system safety as a redundant protection measure, but they cannot serve as essential protection components of the system and cannot replace fuses and circuit breakers specified in standards. In systems where the number of strings connected to one MPPT exceeds two, it is necessary to provide overcurrent protection devices such as fuses or circuit breakers that meet standard requirements. Safety issues cannot be ignored.

English

English  简体中文

简体中文